by DICK ZIGGERS last update:6 Aug 2012

by DICK ZIGGERS last update:6 Aug 2012

Feathers – The Raw Material

The American Association of Feed Control Officials (AAFCO) defines Hydrolysed Poultry Feathers as the product resulting from the treatment under pressure of clean, undecomposed feathers from slaughtered poultry, free of additives and or accelerators. Not less than 75% of its crude protein content must be digestible by the pepsin digestibility method.

There are over 1 million tonnes of feathers produced each year in the U.S. and as the consumption of poultry meat increases so will the production of this valuable raw material. Feathers have a protein content of around 84 percent and does not suffer from the disadvantages of anti-nutritional factors, such as tannins, glucosinolates, lectins and trypsin inhibiting factors. However raw feathers are relatively insoluble and have a very low digestibility of five percent due to the high keratin content and the strong disulphide bonding of the amino acids. Fortunately with the controlled technology available to us today, we are able to convert a relatively insoluble protein into a palatable and highly digestible protein source as seen in Table 1.

Table 1. Crude Protein content and Digestibility of various proteins.

|

Protein

|

C.P. %

|

Ruminant Digestibility %

|

Dig C.P. %

|

|

Feather meal

|

80.4

|

75

|

60.3

|

|

Fishmeal

|

65.0

|

92

|

59.8

|

|

Meat & Bone

|

50.2

|

86

|

43.2

|

|

Soybean Meal

|

45.3

|

90

|

40.8

|

|

Rapeseed Meal

|

35.9

|

84

|

30.1

|

|

Sunflower Meal

|

30.1

|

85

|

25.6

|

Production of Feather Meal

Feather meal (FM) is produced from fresh feathers that are steam hydrolysed under high pressure and temperature (140Ý C) for a period of time sufficient to hydrolyse the chemical bonds of the feathers. Hydrolysing can be carried out in batch cookers or continuos hydrolysers and is then followed by drying. Different processing conditions such as time, temperature, pressure and moisture can have an effect on the digestibility of the protein. Basically there is a rapid increase in the time required for processing when the pressure drops below 207 kPa and a rapid fall in time as the pressure rises above 207 kPa. More recently at least one company has proposed the use of enzymes as a ‘preconditioning agent’ prior to processing in a pressure vessel. The aim of this process is to increase amino acid availability and digestibility.

Feather meal produced under standard conditions from fresh feathers will have the following approximate analysis, Table 2:

Table 2. Typical Analysis of Feather Meal – Ewing 1997

|

Dry Matter

|

90%

|

|

Crude Protein

|

82%

|

|

Digestibility

|

75% min.

|

|

Fat

|

6%

|

|

Ash

|

4%

|

|

Crude Fibre

|

0.6%

|

|

Available Lysine

|

1.8%

|

|

Methionine + Cysteine

|

4.9%

|

|

TMEn

|

3.07 Kcal/g (12.8 MJ/kg)

|

A note on the digestibility values. The official method for determining the in vitro digestibility of feather meal is to use a 0.2% pepsin solution, however recent research work has shown that if a 0.002% solution is used, then the values obtained are more highly correlated with biological assays. The actual value measured is lower than with 0.2% solution however the method appears to be more sensitive and therefore of value in comparing one feather meal to another.

The Energy Value of Feather Meal

Initially work was carried out using broilers as it was considered that the NRC values were too low. Upon investigation of the initial data, Pesti (1990), found that when FM was included in diets at 40% of the ration then the energy value was low, as the animals were unable to digest and absorb the amount of protein offered. However when levels of 20% FM were added to the ration the energy value was much higher than NRC published values (2.36 kcal/g)and it was suggested that a value of 3.07 Kcal/g (12.8MJ/kg) was more appropriate. Similarly Fuller & Dale 1986 found a TME value of 3.07 Kcal/g in feather meals being used commercially in SE USA.

A prediction equation was formulated to predict the nitrogen corrected True Metabolisable Energy:

TMEn (kcal/kg DM) = 2862 + 77(% fat)

The use of this formula showed that a feather meal with 7% fat had an ME value 46 percent higher than that reported by the NRC.

The Quality of Feather Meal Protein

Much of the direct work has been carried out with broilers and as these animals are more sensitive to nutritional change. There is value in considering the results since the feather protein that bypasses the rumen will be subjected to the same digestion, absorption and utilisation that occurs in a broiler.

There is no doubt that in the 50’s and 60’s there was considerable prejudice against feather meal as a result of its low and variable digestibility which at that time was a reflection of the processing conditions. However, a considerable amount of research was carried out at several U.S. universities, (Fuller 1967, Naber et al. 1961, Summers 1969 and Thomas, 1972) which in effect demonstrated that feather meal was a useful protein supplement for inclusion in broiler diets. Corn – soya rations are equally deficient in methionine and cystine. Fuller examined whether feather meal or fish meal could be the sole source of animal protein in a corn soya diet. In order to determine how much of the total sulphur amino acid (TSSA) needs could be met by cystine in the feather meal, only enough methionine was added in each diet to keep the TSAA content equal. There were no significant differences in body weight gain or feed efficiency, demonstrating that at least half of the TSSA requirement can be met with cystine and that feather meal is a good source of this amino acid (Table 3).

Table 3. Feather Meal as a source of total sulphur amino acids.

(Fuller, 1967)

| Calculated Analysis |

Corn-Soya basal ration

|

5% Fish meal

|

5% Feather meal

|

| ME (MJ/kg) |

12.72

|

12.72

|

12.71

|

| Protein % |

24.2

|

24.3

|

24.2

|

| Methionine added % |

0.1

|

0.04

|

0.075

|

| Methionine total % |

0.484

|

0.479

|

0.432

|

| Cystine % |

0.373

|

0.378

|

0.425

|

| Total Sulphur AA % |

0.857

|

0.857

|

0.857

|

| LWG (2-8 weeks) g |

1660

|

1687

|

1683

|

| FCR (feed/gain) |

2.25

|

2.20

|

2.24

|

Summers 1969 reported on the extent to which feather meal can be used in practical broiler rations. The corn-soy and corn-soy-feather meal rations were calculated to be equal in energy and protein. Feather meal protein replaced soy protein up to the point where the first limiting amino acid became limiting in the diet. Hence the starter diet contained 6% and the finisher diet 4.1% feather meal. No differences were observed in growth or feed efficiency of chicks fed the two diets, Table 4.

|

Treatment

|

9 week weight (g)

|

FCR

|

|

Corn-soy diet

|

2077

|

2.27

|

|

Corn-soy-feather diet

|

2082

|

2.27

|

More recently Baler (1981) has demonstrated that as long as there was methionine and lysine supplementation, up to 40% of the crude protein could be supplied by feather meal without affecting growth or feed efficiency.

The data obtained with chicks indicates that upon absorption from the GI tract, that the protein in feather meal can be well utilised. An interesting observation from Cabel et al. (1986), was that when feather meal was included in rations at a level of 4-6% for 7-14 days prior to slaughter, a significant reduction in abdominal fat was observed, without affecting growth or FCR.

Amino Acid Availability

Liu et al. (1989) examined 3 samples of feather meal to determine true amino acid availability (AAA). They found that true AAA ranged from 59.2 lysine to 82.8% arginine, with an overall mean of 72.3% (Table 5). Although these values are lower than other studies they do compare well with studies by Nordheim & Coon (1984).

Table 5. True Amino Acid Availability of feather meal (Liu et al 1989).

|

Amino Acid

|

TAAA %

|

| Lysine |

59.2

|

| Methionine |

74.4

|

| Methionine added % |

0.1

|

| Cystine |

64.2

|

| Leucine |

76.9

|

| Phenylalanine |

79.2

|

| Arginine |

82.8

|

| Overall Average |

73.2 +/- 2.4

|

Feather Meal in Ruminant Diets

Having established from monogastric studies that FM is a valuable protein source in a post ruminal phase of digestion it would therefore be appropriate to investigate the effect of feeding feather meal to the total ruminant. A substantial amount of work with beef cattle has been conducted by Klopfenstein and his colleagues at Nebraska University with dairy trials being conducted at a number of different sites.

Dairy

Moderately producing dairy cattle have been able to obtain all of their protein needs from the passage and subsequent digestion of bacterial and protozoal protein. However with increased genetic merit and the need to produce more per cow, ways have been sought to feed both the cow and the rumen microbial population. Since the amount of bacterial protein produced is maximised, nutritionists have examined the need to supply greater amounts of protein post-ruminally by using either chemically treated or naturally occurring by-pass proteins. Rendered proteins are a source of by-pass protein and in recent times the use of feather meal has been examined in the diets of high producing dairy cattle.

Harris et al. (1997) examined the effect of three levels of feather meal on two protein content diets (Table 6).

Table 6. Effect of various levels of FM on dairy production

|

14%

|

Diet

|

18%

|

Diet

|

|||

|

0% FM

|

3% FM

|

6% FM

|

0% FM

|

3% FM

|

6% FM

|

|

| DMI |

ns

|

Ns

|

ns

|

ns

|

ns

|

ns

|

| BWt Ý |

ns

|

Ns

|

ns

|

ns

|

ns

|

ns

|

| MF% |

ns

|

Ns

|

ns

|

ns

|

ns

|

ns

|

| MY |

0

|

++

|

+

|

0

|

0

|

0

|

| MP% |

0

|

-

|

–

|

0

|

-

|

–

|

They concluded that up to 6% FM had no negative effect on intake or body weight, a positive effect upon milkyield at the lower protein diet and a linear negative effect upon milk protein content. They suggested that the balance of amino acids, low lysine and methionine, was inadequate for maximising milk protein synthesis. Similarly Herbein and Webb (1997), found that 2.2% feather meal was not detrimental to milk production or feed intake. However, the potential for feather meal to increase milk components might be linked to the simultaneous feeding of other high bypass proteins that have complimentary amino acid profiles such as blood meal (BM) which provides more lysine and methionine. With the advent of protected methionine supplements, these combined with low cost feather protein could prove to be very economic for high producing dairy cattle.

Beef

Klopfenstein (1990) evaluated the protein value of urea, soy bean meal, FM, BM and a 50:50 combination of FM and BM when fed to 260 kg calves for a 112 day period. The basal diet was 50% ground corn cobs, 40% corn silage and 10% supplement and supplied 11.5% crude protein and 57% TDN. The urea control calves gained 376 g/day compared to BM alone which gave 735 g/day. The most efficiently used protein sources were BM and FM:BM combination compared to soy bean meal and FM. The excellent performance of the BM:FM combination was suggested as being due to the provision of lysine in the BM.

Table 7. Protein efficiency* of various sources of protein, measured in calves.

|

Ingredient

|

Protein efficiency

|

|

Blood Meal (BM)

|

2.92

|

|

FM:BM (50:50)

|

2.62

|

|

Feathe Meal (FM)

|

1.65

|

|

Soy Bean Meal

|

1.21

|

Conclusion

From monogastric studies we can see that feather meal has a high protein content with a reasonable degree of digestibility. The amino acid composition of the feather meal protein does require supplementation to balance out the low level of lysine and methionine. When incorporated into ruminant diets consideration needs to be given to the amino acid mix and supplement needs to be done, where necessary. Based upon the price of feather meal, nutritionists should consider more regular use of the commodity.

Neville J Chandler – National Renderers´ Association, 52 Packhorse Road,Gerrards Cross, Buckinghamshire SL9 8 EF

References

Ewing, W.N. 1997 The Feeds Directory. Published by Context, UK.

Fuller, H.L. and N.M. Dale 1986. Proc 1986 Georgia Nutrition Conf., p98.

Fuller, H.L. 1967. Proc 1967 Georgia Nutrition Conf. p24.

Harris, B. Jr., Dorminey, D.E. and Van Horn, H.H. 1997 www.poultyegg.org/research/

Herbein, J.H. Jr. and Webb, K.E. Jr. 1997.>www.poultyegg.org/research/

Klopfenstein,T. 1990 Director’s Digest No 177: Fats & Protein Research Foundation

Lui, J.K., Waibel, P.E. and Noll, S.L. 1989 Poultry Science 68:1513

Naber, E.C., Touchburn, S.P., Barnett, B.D. and Morgan, C.L. 1961.

Poultry Science 40:1234.

Nordheim, J.P. and Coon, C.N. 1984. Poultry Science 63:1040

Pesti, G.M., L.D. Faust, H.L. Fuller, H.M. Dale and F.H. Benhoff 1986

Poultry Sci. 65:2258

Pesti, G.M. 1990 Fats & Proteins Research Foundation, Directors Digest 172

Summers, J.D. 1969. Feedstuffs, March16. p.36.

Thomas, O.P., bossard, E.H., Nicjolson, J.L. and Twinning, P.V. Jr. 1972. Proc. Maryland Nutrition Conf. p86.

Appendix 1: COMPARITIVE FEATHER MEAL ANALYSES (as fed basis /kg product)

|

NRA

|

NRC

|

INRA

|

ACV

|

MAAF

|

|

|

**

|

(USA)

|

(France)

|

(Neth.)

|

(UK)

|

|

| Dry Matter % |

91

|

93

|

93

|

90.6

|

90.7

|

| POULTRY | |||||

| ME broilers |

3240

|

2360

|

2800

|

3150

|

2968

|

| ME layers |

3240

|

-

|

2800

|

3200

|

-

|

| RUMINANT | |||||

| TDN% |

70

|

65

|

-

|

-

|

-

|

| ME kcal |

3350

|

2480

|

2892

|

-

|

-

|

| PIGS | |||||

| TDN % |

66

|

62

|

-

|

-

|

-

|

| DE kcal |

3730

|

2731

|

3730

|

-

|

-

|

| ME kcal |

3240

|

2215

|

3240

|

-

|

-

|

| CRUDE ANALYSIS | |||||

| Crude Protein % |

83

|

84.9

|

85.8

|

85.7

|

80.9

|

| Fat % |

5.0

|

2.9

|

3.5

|

5.4

|

5.8

|

| Ash % |

3.0

|

3.5

|

3.17

|

2.1

|

2.3

|

| Crude Fibre % |

1.5

|

1.4

|

-

|

0.0

|

4.3

|

| DCP % ruminants |

85

|

-

|

86

|

86

|

-

|

| DCP % pig |

85

|

-

|

75

|

87

|

-

|

| DCP % poultry |

75

|

-

|

-

|

77

|

-

|

| MINERALS | |||||

| Calcium % |

0.45

|

0.26

|

0.20

|

0.34

|

0.51

|

| Phosphorous % |

0.40

|

0.67

|

0.70

|

0.18

|

0.28

|

| Magnesium % |

0.15

|

0.20

|

0.18

|

0.20

|

0.03

|

| Potassium % |

0.20

|

0.29

|

0.24

|

0.15

|

0.14

|

| Sodium % |

0.20

|

0.70

|

-

|

0.01

|

0.13

|

| Sulphur % |

1.50

|

1.50

|

0.90

|

-

|

1.64

|

| Iron mg |

70.0

|

76.0

|

70.0

|

-

|

61.00

|

| Manganese mg |

15.0

|

13.0

|

7.0

|

-

|

18.00

|

| Selenium mg |

0.10

|

0.84

|

0.30

|

-

|

0.07

|

| Zinc mg |

40.0

|

69.0

|

70.0

|

-

|

13.80

|

| AMINO ACIDS | |||||

| Lysine % |

1.85

|

2.32

|

1.84

|

1.63

|

1.82

|

| Methionine % |

0.55

|

0.55

|

0.53

|

0.60

|

0.55

|

| Cysteine % |

3.50

|

3.24

|

3.55

|

3.34

|

3.76

|

| Met + Cys % |

4.05

|

3.79

|

4.08

|

3.94

|

-

|

| Threonine % |

4.00

|

3.97

|

3.91

|

4.20

|

4.10

|

| Tryptophan % |

0.50

|

0.52

|

0.43

|

0.51

|

-

|

| Isoleucine % |

4.10

|

4.06

|

3.95

|

4.54

|

4.10

|

| Leucine % |

7.00

|

6.94

|

11.58

|

7.03

|

6.90

|

| Valine % |

5.00

|

3.06

|

6.88

|

7.20

|

6.30

|

| Histidine % |

0.75

|

0.99

|

0.58

|

0.51

|

1.20

|

| Arginine % |

6.00

|

7.05

|

5.66

|

5.91

|

5.39

|

| Glycine % |

6.50

|

6.44

|

-

|

6.86

|

6.52

|

| Serine % |

10.0

|

9.26

|

-

|

12.34

|

9.80

|

| Phenylalanine % |

4.00

|

3.05

|

-

|

4.03

|

4.21

|

| Tyrosine % |

2.00

|

2.32

|

-

|

-

|

1.84

|

1. What kind of yeast product could be used in animal nutrition?

Yeasts have been used in feed for many years. Both the Bovine Spongiform Encephalopathy crisis (mad cow disease), and the increasing concern of customers about their diet have lead to an increased use of “clean” protein sources, such as yeast, in animal feed.

After years of development, particularly extensive research in recent years, variety of yeast and its derivative products in animal nutrition have been widely used, including:

Active Yeast, a kind of probiotic yeast;

Selenium Yeast, as a source of organic selenium;

Autolyzed Yeast, which is sometimes called Yeast Autolysate, as a kind of natural growth promoter.

Yeast Cell Wall, as an effective immune enhancer.

2. What is the difference between the active yeast for feed and for bakery?

Both are active yeasts with strong activity, which, however, are originated from different strains and by different fermentative techniques.

Feed Active Yeast possesses outstanding adaptability on the low pH condition of the gastrointestinal tract works as a probiotic product. It helps to regulate intestinal microflora and improve feed digestibility.

Baker’s Yeast is active used for the production of baked food, such as bread and buns. It is good at gas production and helps to make the food fluffy and savory.

3. What’s the difference between Active Feed Yeast and Brewer’s Yeast?

Active feed yeast is dried pure yeast product in dormant period without any carrier, within more than 80% is live and the total number of viable cells is more than 15 billion per gram.

Brewer’s Yeast is the yeast byproduct of beer fermentation. Compared to active feed yeast, the Brewer Yeast contains few live cells and be used as protein source in feed.

4. Definition of Selenium Yeast.

It is a pure yeast product contains high concentration of selenium.

Under appropriate conditions, yeast (Saccharomyces cerevisiae) accumulated large amount of inorganic selenium, and incorporated them into organic compounds by liquid fermentation process.

The content of organic selenium reaches to 2000PPM.

5. Why should the selenium be supplemented?

As a essential trace element, selenium deficiency is closely related to the incidence of more than 40 kinds of human diseases, such as cardiovascular disease, diabetes, immune deficiency, Keshan disease and even cancer. More and more attentions have been paid on this problem in recent years.

Soil selenium deficiency is a common problem in the world. There are more than 40 countries and/or regions around the world that face this problem. Food supply alone can not meet the needs of selenium in animals and therefore additionally supplement is necessary.

6. What’s the difference between organic and inorganic selenium?

Selenium occurs naturally in a number of inorganic forms, including selenide-, selenate-, and selenite-containing minerals.

In living systems, selenium is found in the amino acids selenomethionine, selenocysteine, and methylselenocysteine. In these compounds, selenium plays a role analogous to that of sulfur. Another naturally occurring organic selenium compounds is dimethyl selenide. The selenium yeast, rich in selenomethionine and selenocysteine, is an ideal organic selenium source.

The organic selenium exhibit higher toxicological safety, physical activity and absorption rate than inorganic selenium.

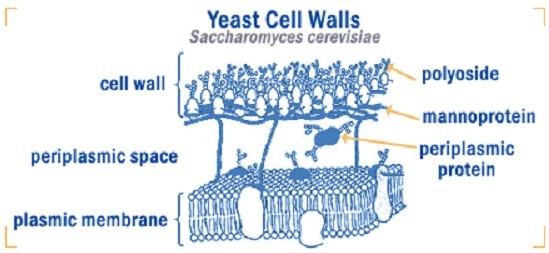

7. What’s Yeast Cell Wall?

Yeast Cell Wall represents 26 – 32 % of the dry weight of Saccharomyces and other kinds of yeast. This Cell Wall is a structural component and gives the yeast its shape and rigidity.

8. What’s the functional ingredients in Yeast Cell Wall?

Yeast Cell Wall is a non-specific stimulator of the immune system of both human and animals.

Yeast Beta-Glucan – an ingredient of Yeast Cell Wall -can stimulate the cells of the immune system (macrophages) and help to overcome bacterial infections.

Mannanoligosaccharide (MOS), another ingredient of Yeast Cell Wall, has been demonstrated to bind to pathogenic bacteria in the gut and then carry them through and out of the intestinal tract and prevent diarrhea.

9. What’s the difference between Autolyzed Yeast and Yeast Extract?

Both are resulted from the selfdigestion of the proteins and other constituents of the yeast by the enzymes contained in the yeast cells.

However, there are two main differences between Yeast Extract and Autolyzed Yeast:

• The autolysis stage of the production process is shorter for Autolyzed Yeast compared to Yeast Extract, resulting in a partial hydrolysis of the yeast constituents.

• Cell Walls are not removed from Autolyzed Yeast, resulting in a product which is only partially soluble in water.

10. What’s the difference between Autolyzed Yeast and Active Yeast?

Active Yeast is the yeast product with the whole activity and worked as probiotics via metabolism and multiplies.

Autolyzed Yeast is inactive yeast product, used as a source of high quality proteins, peptides and amino acids and nucleotides.

Feather meal, feathermeal, hydrolyzed feather meal, poultry feather meal, hydrolyzed poultry feather meal

Feathers are a by-product of broiler, turkey and poultry processing operations. Variability of feather meal between batches and between plants can be quite high due to differences in what is included (heads, feet, skin, etc.).

Pressurized cooking of feathers is the primary method of processing used in preparing feather meal. Some bacteria have been identified that produce a feather digesting enzyme, that will convert the protein fraction into a digestible form (Shih, 1993). Pepsin digestibility is used as method of assessing the quality of feather meal. Normally a pepsin digestibility of 75 % is considered to be a minimum value to assure that the feather meal has been adequately processed.

Feather meals needs to be tested (pepsin digestibility) to assure that it has been processed properly. Care need to be taken to select other supplemental protein sources that will complement to poor amino acid profile of the feather meal, when formulating rations.

Feeding a combination of feather and blood meals resulted in the best growth in calves (Blasi et al., 1991). When feather meal was incorporated into liquid supplements to replace a portion of the CP provided by urea, average daily gain and reproductive performance was improved in mature beef cows (Pate et al., 1995). Calves fed feather meal as their primary supplemental protein didn’t respond to when supplemental lysine or methionine was fed (Klemesrud et al., 1998).

Feather meal has been found to be an effective supplemental protein source for lactating dairy cattle (Harris et al., 1992). Combination of feather meal and blood meal was shown to be acceptable as a protein source in dairy cattle (Johnson et al., 1994). Feeding a combination of feather meal and blood meal was found to increase milk production in dairy cattle (Grant et al., 1998).

The rate of gain in lambs was increased when feather meal replaced soybean meal (Thomas et al., 1994). Feather meal was found to increase ADG when it replaced soybean meal and urea in sheep diets (Punsri, 1991). Supplementation with feather meal showed no effect on straw digestion in lambs (Thomas et al., 1994). Wool fiber diameter and sulfur content of wool didn’t differ in lambs fed feather meal (Thomas et al., 1994).

Swine feeding trials found that when feather meal replaced soybean meal that ADG and FC declined (Duangsmorn Sinchermsiri et al., 1989). High levels (5 and 7.5 %) of dietary feather meal decreased digestibility of DM and CP, decreased loin eye area, decreased FC and decreased feed intake in swine (Rachan Buaban, 1988). Feather meal when fed up to 10% of diet didn’t was not found to affect DDM or DCP of the diet in swine (Rachan Buaban et al., 1989). In growing-finishing swine rations feather meal could provide up to 25 % of the dietary protein with significantly affecting performance (Khajarern et al., 1982b). No difference in performance was observed when up to 4 % feather meal was fed to swine 0-4 weeks of age and up to 8 % could be fed to the 4 to 8 week old age group (Khajarern et al., 1982b). Levels up to 10 % of feather meal in the diets of swine didn’t affect total diet DM or CP digestibility, but as feather meal increased the Biological Value of the dietary CP decreased (Rachan Buaban et al., 1989).

Pullets fed feather meal was found to grow satisfactorily, the addition of methionine was found to improve performance (Khajarern et al., 1982a). The effect of supplementing feather meal with 0.2 to 0.5 % methionine was found to increase carcass quality in broilers and egg weight and shell thickness in layers (Miranda et al., 1981)

Feather meal can provide up to 50 % of the supplemental protein for young growing duckling, 100 % for older growing ducks and 50 % in ducks that are laying (Sucheep Suksupath, 1980).

In carps, feather meal was found to between poultry by-product meal and blood meal in its feeding value (Trzebiatowski et al., 1982).

DATASHEET UNDER CONSTRUCTION. DO NOT QUOTE. http://www.feedipedia.org/node/213 Last updated on October 9, 2011, 15:22

| IMPORTANT INFORMATION: This datasheet is pending revision and updating; its contents are currently derived from FAO’s Animal Feed Resources Information System (1991-2002) and from Bo Göhl’s Tropical Feeds (1976-1982). |

| Main analysis | Unit | Avg | SD | Min | Max | Nb | |

| Dry matter | % as fed | 92.1 | 1.9 | 88.3 | 95.7 | 107 | |

| Crude protein | % DM | 85.7 | 5.0 | 73.8 | 96.5 | 118 | |

| Crude fibre | % DM | 0.9 | 0.6 | 0.3 | 2.9 | 18 | |

| NDF | % DM | 55.8 | 1.9 | 53.8 | 57.5 | 3 | |

| ADF | % DM | 6.5 | 2.9 | 2.0 | 11.7 | 10 | |

| Lignin | % DM | 5.5 | 2.2 | 4.1 | 8.0 | 3 | |

| Ether extract | % DM | 6.7 | 2.5 | 2.5 | 13.6 | 46 | |

| Ether extract, HCl hydrolysis | % DM | 9.5 | 1.8 | 4.8 | 12.9 | 57 | |

| Ash | % DM | 5.5 | 3.8 | 1.3 | 16.0 | 115 | |

| Total sugars | % DM | 0.3 | 0.2 | 0.2 | 0.6 | 4 | |

| Gross energy | MJ/kg DM | 23.5 | 0.4 | 22.7 | 24.0 | 18 | * |

| Minerals | Unit | Avg | SD | Min | Max | Nb | |

| Calcium | g/kg DM | 12.7 | 4.1 | 3.6 | 16.8 | 22 | * |

| Phosphorus | g/kg DM | 8.2 | 1.9 | 2.6 | 8.8 | 22 | * |

| Potassium | g/kg DM | 1.3 | 0.2 | 1.0 | 1.5 | 10 | |

| Sodium | g/kg DM | 1.3 | 0.2 | 1.0 | 1.4 | 10 | |

| Magnesium | g/kg DM | 0.9 | 1.3 | 0.4 | 4.5 | 10 | |

| Manganese | mg/kg DM | 16 | 6 | 7 | 21 | 7 | |

| Zinc | mg/kg DM | 142 | 20 | 106 | 157 | 7 | |

| Copper | mg/kg DM | 10 | 1 | 7 | 11 | 6 | |

| Iron | mg/kg DM | 625 | 213 | 246 | 833 | 6 | |

| Amino acids | Unit | Avg | SD | Min | Max | Nb | |

| Alanine | % protein | 4.6 | 0.3 | 4.1 | 5.3 | 19 | |

| Arginine | % protein | 6.7 | 0.4 | 5.6 | 7.4 | 24 | |

| Aspartic acid | % protein | 6.7 | 0.2 | 6.5 | 7.0 | 19 | |

| Cystine | % protein | 4.3 | 0.3 | 4.0 | 5.0 | 23 | |

| Glutamic acid | % protein | 10.6 | 0.9 | 8.6 | 11.6 | 19 | |

| Glycine | % protein | 7.3 | 0.5 | 6.1 | 8.3 | 21 | |

| Histidine | % protein | 0.8 | 0.2 | 0.5 | 1.4 | 24 | |

| Isoleucine | % protein | 4.9 | 0.4 | 3.5 | 5.3 | 25 | |

| Leucine | % protein | 8.0 | 0.5 | 7.3 | 9.2 | 26 | |

| Lysine | % protein | 2.1 | 0.2 | 1.7 | 2.6 | 27 | |

| Methionine | % protein | 0.7 | 0.1 | 0.6 | 1.0 | 26 | |

| Phenylalanine | % protein | 4.7 | 0.4 | 3.9 | 5.4 | 25 | |

| Proline | % protein | 9.4 | 0.3 | 8.8 | 10.0 | 17 | |

| Serine | % protein | 11.4 | 0.9 | 8.5 | 12.0 | 19 | |

| Threonine | % protein | 4.6 | 0.4 | 3.7 | 5.3 | 26 | |

| Tryptophan | % protein | 0.6 | 0.1 | 0.5 | 0.8 | 7 | |

| Tyrosine | % protein | 2.5 | 0.3 | 2.1 | 3.3 | 18 | |

| Valine | % protein | 7.2 | 1.1 | 5.1 | 8.1 | 25 | |

| Ruminant nutritive values | Unit | Avg | SD | Min | Max | Nb | |

| OM digestibility, Ruminant | % | 76.8 | 4.1 | 72.0 | 82.7 | 6 | |

| Energy digestibility, ruminants | % | 82.6 | 1.0 | 71.0 | 82.6 | 4 | * |

| DE ruminants | MJ/kg DM | 19.4 | 0.5 | 15.9 | 19.4 | 4 | * |

| ME ruminants | MJ/kg DM | 13.3 | 0.5 | 13.3 | 14.5 | 4 | * |

| Nitrogen digestibility, ruminants | % | 74.1 | 5.9 | 69.0 | 85.2 | 6 | |

| a (N) | % | 15.8 | 1 | ||||

| b (N) | % | 48.3 | 1 | ||||

| c (N) | h-1 | 0.055 | 1 | ||||

| Nitrogen degradability (effective, k=4%) | % | 44 | * | ||||

| Nitrogen degradability (effective, k=6%) | % | 39 | 28 | 39 | 2 | * | |

| Pig nutritive values | Unit | Avg | SD | Min | Max | Nb | |

| Energy digestibility, growing pig | % | 88.7 | * | ||||

| DE growing pig | MJ/kg DM | 20.8 | * | ||||

| MEn growing pig | MJ/kg DM | 18.9 | * | ||||

| NE growing pig | MJ/kg DM | 11.6 | * | ||||

| Nitrogen digestibility, growing pig | % | 72.1 | 71.1 | 73.0 | 2 | ||

| Poultry nutritive values | Unit | Avg | SD | Min | Max | Nb | |

| AMEn cockerel | MJ/kg DM | 12.5 | 0.5 | 12.5 | 14.4 | 5 | * |

| AMEn broiler | MJ/kg DM | 11.7 | * | ||||

| Fish nutritive values | Unit | Avg | SD | Min | Max | Nb | |

| Energy digestibility, salmonids | % | 63.7 | 57.4 | 70.1 | 2 | ||

| Nitrogen digestibility, salmonids | % | 64.4 | 58.0 | 70.8 | 2 |

The asterisk * indicates that the average value was obtained by an equation.

ADAS, 1988; ADAS, 1990; Aderibigbe et al., 1983; AFZ, 2011; Church et al., 1982; Dewar, 1967; Fialho et al., 1995; Furuya et al., 1988; Hajen et al., 1993; Hegedüs et al., 1990; Howie et al., 1996; Huston et al., 1971; Jongbloed et al., 1990; Kamalak et al., 2005; Kellems et al., 1998; Knabe et al., 1989; Knaus et al., 1998; Latshaw et al., 1994; McDowell et al., 1974; Munguti et al., 2009; Nengas et al., 1995; NRC, 1994; Pansri et al., 1987; Papadopoulos et al., 1986; Papadopoulos, 1986; Petit, 1992; Quilici, 1967; Schang et al., 1982; Swanek et al., 2001

Last updated on 24/10/2012 00:43:31

TABLE UNDER CONSTRUCTION. DO NOT QUOTE.